Custom Mixing Rubber Compound

Good quality rubber products start with consistency compounding

SIAMNAVAKAM

The rubber compound we provide is formulated and mixed specifically for each customer to ensure that it meets customer’s applications and required specifications. The main components of the rubber compound are:

Rubber

(Natural & Synthetic rubber)

Oil

Carbon Black

Others

(Accelerator, Curing Agent, etc.)

List of Rubber we work with

- Natural Rubber (NR)

- Butadiene Rubber (BR)

- Acrylonitrile Butadiene Rubber (NBR)

- Stryrene Butadiene Rubber (SBR)

- Blend of NBR and PVC (NBR / PVC)

- Butyl Rubber (IIR)

- Polychloroprene Rubber (CR)

- Ethylene Propylene Diene Monomer (EPDM)

- etc.

Industries we served

Automotive

Construction

Marine

Mining and Conveyor belt

Electronics

Moulding Products

Off-road Tire

What we supply to you

Development

Formulas are developed by our chemists and technical staffs to meet customers’ requirements. Materrials are carefully prepared to create a desirable physical properties. Process and desired properties must be confirmed before launching new products.

Mixing

Formulas are developed by our chemists and technical staffs to meet customers’ requirements. Materrials are carefully prepared to create a desirable physical properties. Process and desired properties must be confirmed before launching new products.

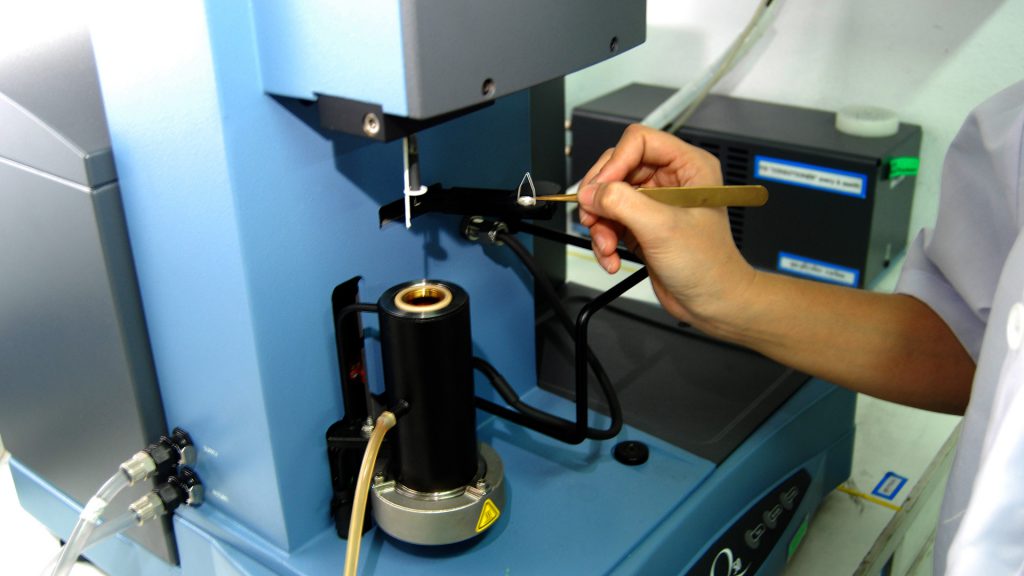

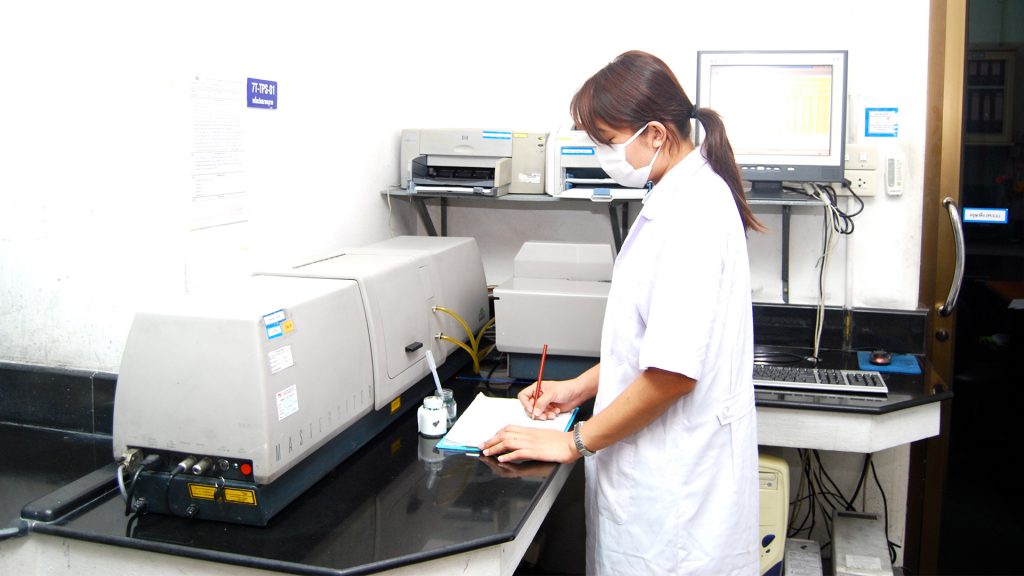

Controlling

Raw materials are tracked throughout the entire compounding process, with fully laboratory instruments, all properties of the rubber compound are measured. Finished goods from each batch are tested to ensure that they are conform to desired properties.

Delivery

At Siamnavakam, we focus on all elements that support on-time delivery. Once commitment is made, we do everything within our control to adhere to the delivery date. You can count on us to deliver-on time, every time.

Siamnavakam Factory

88/8 SAINOI-LATBUALUNG RD., KLONG-KWANG, SAINOI, NONTHABURI, THAILAND

Tel : +66-2-1905581-9

Fax: +66-2-1905586

EMAIL : info@siamnavakam.com

Siamnavakam Office

71/30-31 M.5 BANGGROY-SAINOI RD., BANGBUATHONG, NONTHABURI, THAILAND 11110

Tel : +66-2-9036691-3

Fax : +66-2-9036694

MB : 085-4886080-83

MB : 089-2049944 HOTLINE

MB : 089-3179007 HOTLINE

MB : 089-6413851 HOTLINE

EMAIL : info@siamnavakam.com